Increasing work efficiency by up to 40%

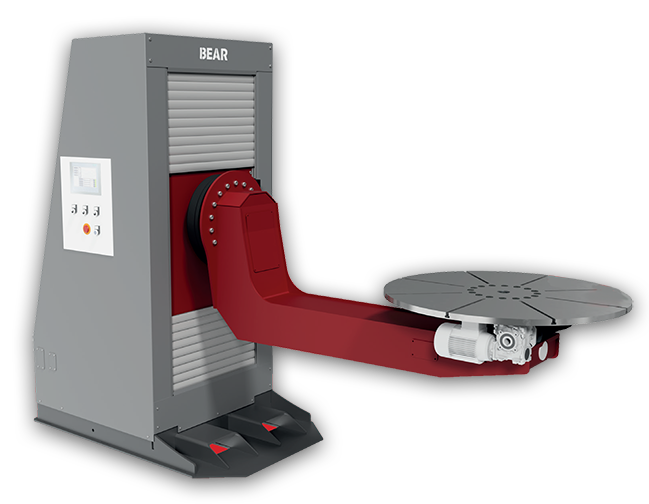

Positioners are mainly intended for positioning cumbersome and heavy items in order to achieve optimal working conditions and increase safety, efficiency, quality, and ergonomics for workers.

The positioners we manufacture are designed to lift items weighing from 250 kg up to even 24 tons. Based on individual customer requirements, it is possible to design and manufacture manipulators with even greater load capacity.

Benefits and advantages

-

Increasing work efficiency by up to 40% through optimal object positioning - this has resulted in a short payback time for the device

-

Increasing production efficiency does not require additional space in the production hall

-

Better quality of welded joints - always possible to weld in a downhand position

-

Solid device construction ensures long-term, failure-free operation

application

Useful for positioning elements in:

welding

cleaning

assembly

Each of the positioners can be specifically made to meet individual customer requirements.

The variety of BEAR positioner models allows for the perfect solution to be

tailored to the specifics of our work. SPR, BE, and PX product lines are used for classic

element positioning. The RO and RT lines were created to cooperate with robots of

leading brands.

MAKE AN APPOINTMENT FOR A FREE PRESENTATION

Call or email us to arrange a presentation and meeting with a BEAR specialist!

support in all activities

BEAR offers support in all activities related to the implementation of the supply of a comprehensive workstation:

-

Analysis of customer needs and determination of detailed technical purposes

-

Evaluation of possibilities and proposal of a technical solution

-

Consultations with the customer, serious and quick negotiation of sales contracts

-

Design, construction, and realization

-

Testing, welding of test samples

-

Assembly, training, handover to the customer

A high-performance hydraulic system is used to lift and tilt elements, whose safety is guaranteed by multi-stage protections. If necessary, positioners can be modified depending on requirements: table size, arm length, control system, rotation speed, etc.

AVAILABLE BEAR POSITIONER SERIES

contact

If you have any questions related to BEAR positioners, please feel free to contact us by phone and email. You can also use the contact form next to it. We will respond promptly.

-

+48 784 692 849

-

+48 606 981 703

-

+48 668 793 236

-

+48 664 939 883

-

contact@bearwelding.eu

-

P.P.H.U. TokFrez | Targowisko 559 | 32-015 Kłaj

-

TokFrez is one of the best recognized companies specializing in the production of Trapezoidal, Ditch and Hydraulic Buckets and Long Reach arms in Poland. We have been operating in the market since 2004. We are also a manufacturer and distributor of BEAR brand welding positioners.